Online Buy Wholesale water transfer printing film from China water transfer printing film

Water Transfer Printing | Liquid Concepts 501-455-5500 Your one stop shop to customize your world Offering water transfer printing supplies and professional coating services Order supplies to do it yourself Whether you are a hobbyist or a professional, our selection of custom films and hydrographics equipment are the best in the industry.

Create great effects on surfaces with Water Transfer Printing

Water transfer printing (WTP) is popular in several industries due to its low cost and ability to coat complicated and heat-sensitive surfaces. However, the primers and activators used in WTP release volatile organic compounds that pollute the environment, and the transferred patterns may suffer from deformation.

WATER TRANSFER PRINTING Adelaide Auto Refinishers

Water Transfer Printing is an immersion printing technique used to decorate many types of materials and three-dimensional objects, even particularly complex ones. Sometimes this technique is also called Cubik-Printing, Immersion Printing or hydrographic. How does Water Transfer Printing process take place?

Water Transfer Printing in Mumbai, Andheri East by H2O Graphix (A Unit Of Photokina Chemicals

Human exposure to microplastics (MPs) through drinking water has drawn serious concern recently because of the potential adverse health effects. Although there are reports on the occurrence of MPs in bottled water, little is known about the abundance of a whole spectrum of MPs with sizes ranging from 1 µm to 5 mm due to the restrictions of conventional MPs detection methods. Some studies.

Aikka Water Transfer Printing YouTube

Water transfer printing, also called hydrographics or camo dipping, is the process that transfers an image or pattern to a 3D surface. Whether it's your metal, wood, plastic, stone, Bakelite, or ceramic products, hydro dipping puts you in charge. It's your stuff your way. So, pick your hydrographics film and make it happen. My Dip Kit Uses

Water Transfer Printing / Pintura Hidrográfica Hidrográfica

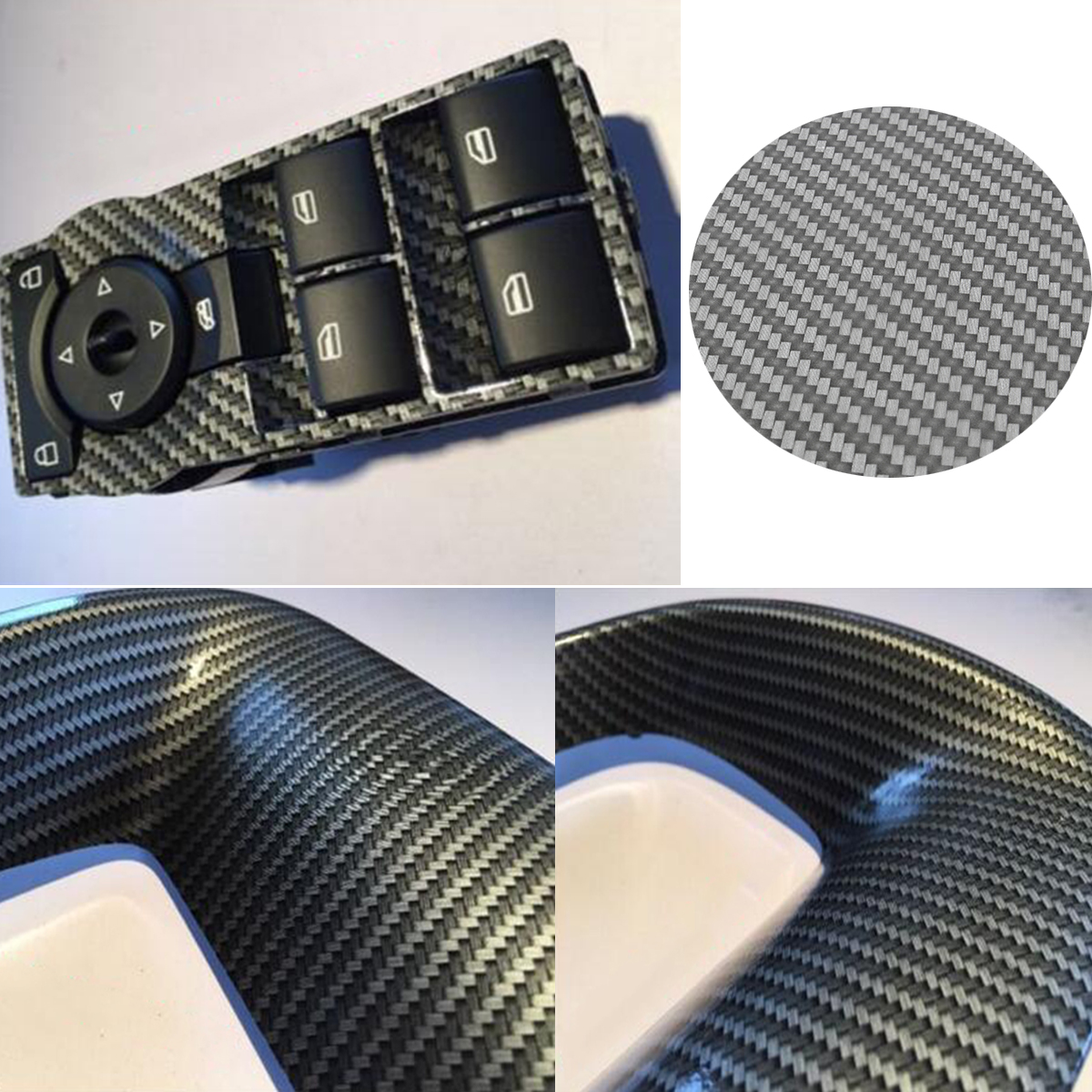

Hydrographics is a process where an existing part or product can receive a custom or new finish. It is also known as water transfer printing, camo-dipping, hydro-imaging or aqua-graphics. There are currently over 1000 different patterns/films to choose from that range from camo to skulls and anything in between.

What Is Water Transfer Printing (WTP)? Market Prospects

Water transfer printing, also known as immersion printing, water transfer imaging, hydro dipping, watermarbling, cubic printing, Hydrographics, or HydroGraphics, is a method of applying printed designs to three-dimensional surfaces. The resulting combinations may be considered decorative art or applied art.

Hydrographics Water Transfer Printing

What is Water Transfer Printing? What type of items can be dipped? How durable is Water Transfer Printing? How long does the process take from start to finish? What do I need to start a hydrographics business? How scratch resistant is the final product? What is the maximum temperature a processed part can be exposed to?

Water Transfer Printing HydroGrafik.dk YouTube

Water Transfer Printing - Hydrographics - Hydro Dipping | HG Arts 2017 - YouTube © 2024 Google LLC Hydro Dipping or HydroGraphics, also known as immersion printing, water transfer printing,.

Hydrographics 101 for Manufacturing Resources Fast Radius

Water transfer printing (WTP), also known as immersion printing, water transfer imaging, hydro dipping, watermarbling, cubic printing, water printing, Hydrographics, or HydroGraphics. Water transfer printing technology is a printing technology that uses water pressure to hydrolyze the transfer paper/plastic film with color patterns.

Water Transfer Printing Film Hydrographic Film Hydro Dip Carbon Fiber

Printing Supplies & Services. Liquid Print has spent years of research developing our own proprietary line of equipment, supporting chemicals, paints and films for the Hydro Dipping / hydrographic / water transfer industry. All of our products are commercial grade and used in OEM applications worldwide. BUY NOW.

Water Transfer Printing Process Download Scientific Diagram

Liquid Concepts carries all the hydro dipping films, hydrographics tanks and supplies to help you get into the exciting world of water transfer printing. We also offer training in hydro dipping techniques, both online and in-house at our facility in Alexander, Arkansas. Customize your favorite gear with vivid, high quality hydro dipping films.

Water Transfer Printing Hydrographics Applying Printed Designs To ThreeDimensional Objects

Yes! All you need is film, activator, and a tub of water. Alternatively, can begin water transfer printing at home using a readymade kit (See suggestions below). Water transfer printing doesn't require any previous skill or experience with hydro dipping, and supplies are quite affordable.

Feast Your Eyes on WaterTransfer Printing

What is Water Transfer Printing? Water Transfer Printing is a decorative coating technology that allows you to apply detailed patterns and artwork onto 3-dimensional objects. This coating method is used widely for decorating automotive dash panels, aviation bulkheads, rifle stocks, and many other items. Want to learn more about hydro dipping?

Water Transfer Printing by 3Decor YouTube

Hydrographic Printing, also know as Water Transfer Printing, allows patterns and designs to be applied to any shaped objects. Any object that can hold a base coat and be safely submerged in water can be dipped. Surfaces such as dashboards, hunting equipment, camouflage items, automotive parts and many others, can be customized with this process.

Water transfer printing, 3D Hydrographics & Cubic Printing Wicked Coatings

applied tension. Our results demonstrate that expansion-enhanced water transfer printing is a promising fabrication process for conformable electronics on large 3D surfaces. 1. Introduction Currently, integrated circuits and microelectromechanical systems (MEMS) have to be fabricated on rigid planar wafers that cannot fit the shape of a 3D object.