Types Of Pumps Plumbing Help

1 Description 2 Functions 3 Summary of Designations and Functions 4 Location 4.1 PSE Pump 4.2 Inlet Air Filter 5 Part Numbers 6 Specification Values (Obtained by Measurement) 6.1 Pressure Regulated Switch 6.2 Pressure at MKL Port 6.3 Solenoid Coil Resistance 7 Baseline Pressure Tests 8 Issues 8.1 Pump Fails to Work Due to Pneumatic Leaks

What Are the Three Types of Centrifugal Pumps? Flowmore Pumps

ELECTRIC SINGLE LINE DIAGRAM 6"MALE CAMLOCK w/CAP (316 S.S.) INFLUENT PIPE DROP BOWL NOTES: ANCHORS TO BE CONSTRUCTED OF 316 STAINLESS STEEL "H.A.S." ROD BY HILTI OR EQUAL). THE ANCHORING SYSTEM SHALL INCLUDE ADHESIVE (HILTI H.V.U. OR EQUAL) WITH AN EMBEDMENT DEPTH OF 4 1/4". INSTALL DROP BOWL AFTER THE WET WELL LINER IS INSTALLED.

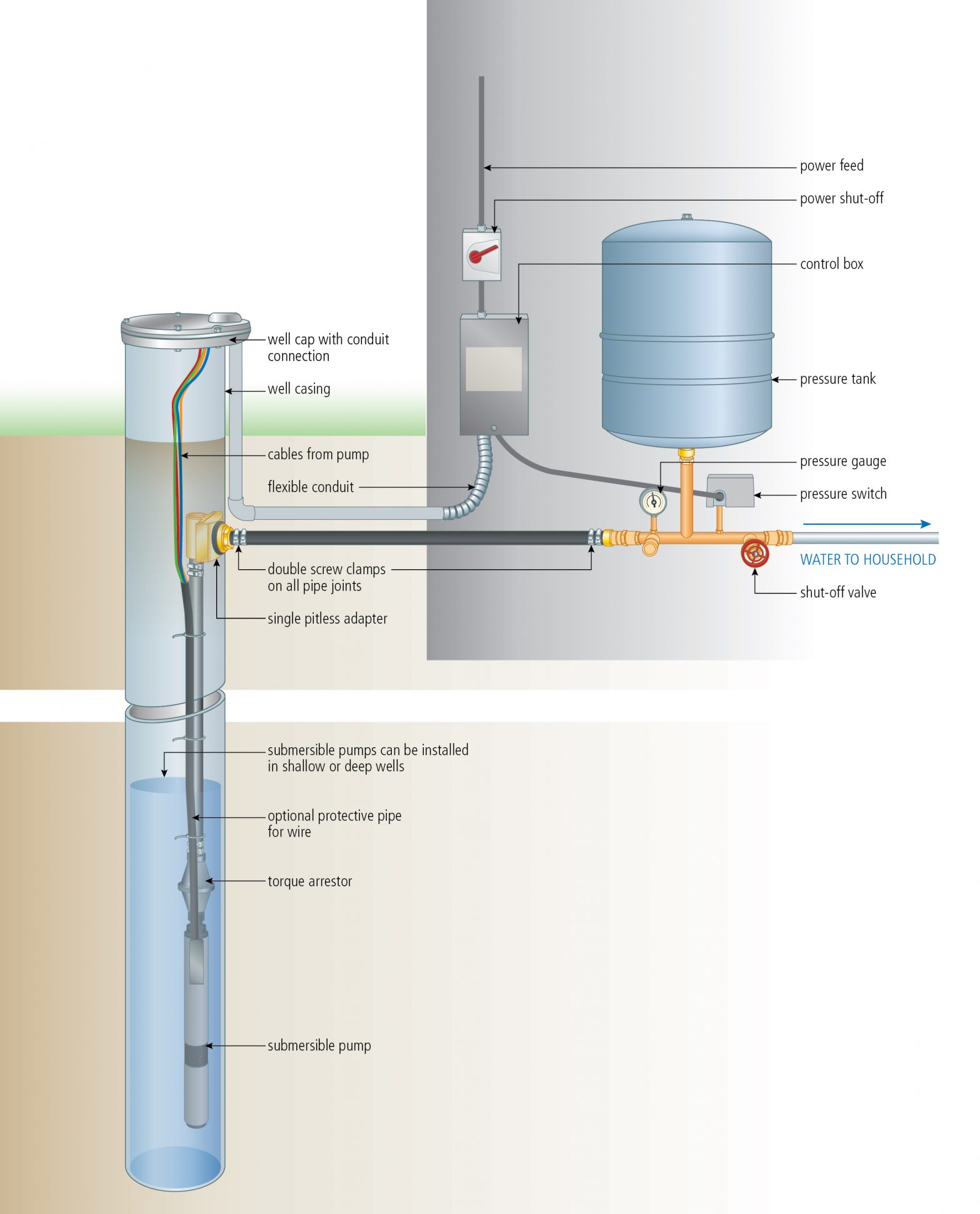

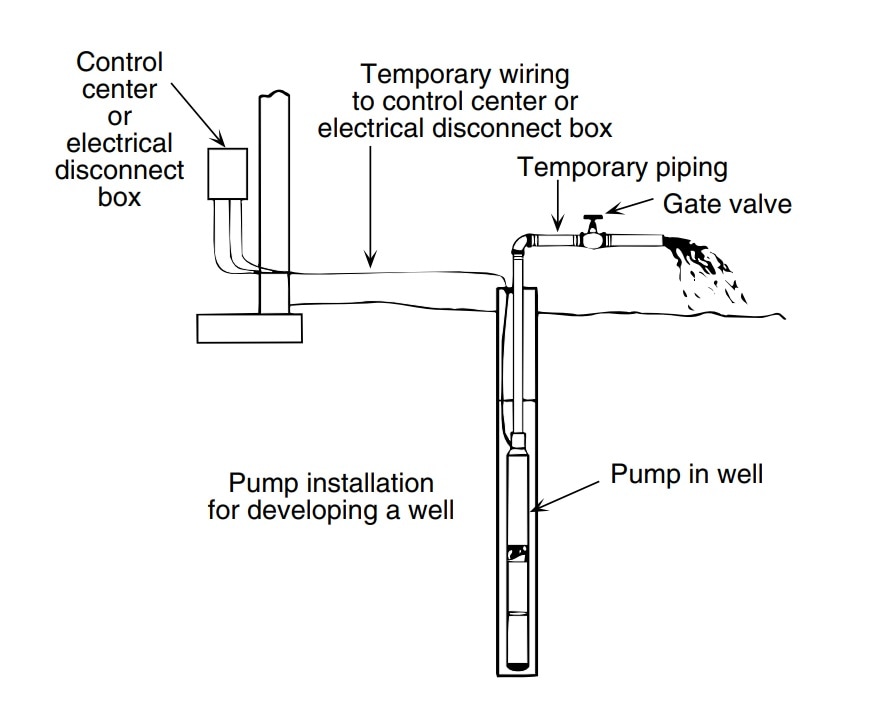

INSTALL A SUBMERSIBLE PUMP 6 Lessons for doing it right

controller shall have its own individual pressure-sensing line. 4.30.2 The pressure-sensing line connection for each pump, including jockey pumps, shall be made between that pump's. discharge.

2003 Gmc Sierra 1500 Abs Pump Lines Diagram

The completed reactance diagram is shown in Figure 5: TXLs should be j0.13724 (my correction) Figure 5 - Single line reactance circuit diagram (reactances shown on a per-unit basis) 7. Calculate Operating Conditions of the Motors If the motors are operating at 12 kV, this represents 12 kV/13.8 kV = 0.87 per-unit voltage.

Submersiblepumpdiagram Aarohi Embedded Systems Pvt. Ltd.

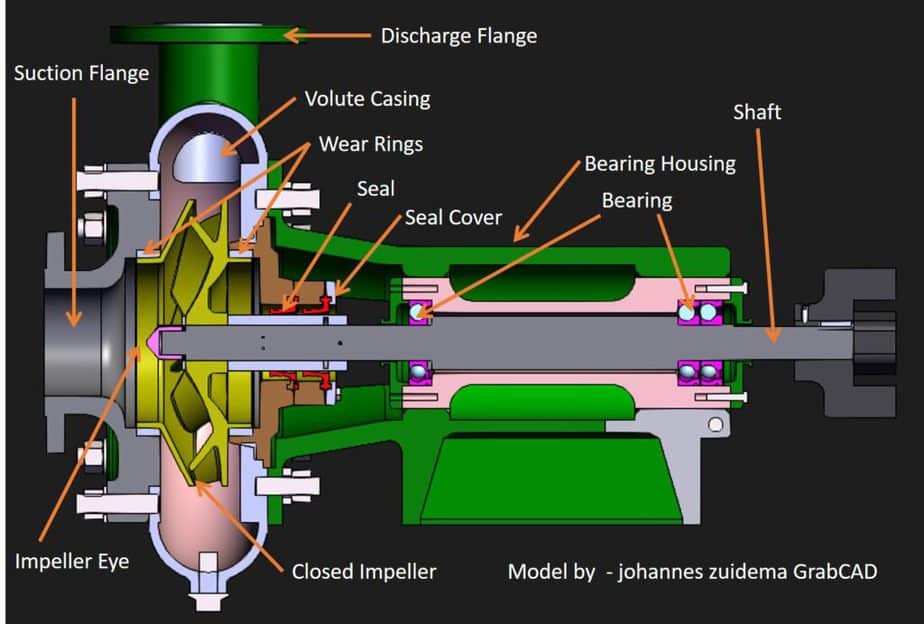

Centrifugal Pump Diagram In this article, I am going to discuss the Centrifugal Pump Diagram. I will show you various centrifugal pumps with a schematic and cross-section to show you the different parts inside. I have covered the following centrifugal pump diagram with parts. Single stage open impeller pump Single stage closed impeller pump

How to do Pump Piping with Layout Explained PIPING GUIDE

The pump is the common point that is bringing all these circuits down. New pump. I installed a new pump, and the voltage did not go below 21V on the initial turn on, and there are no more DTCs stored for the relay feedback circuit or command circuit (Figure 8). I have also marked rulers on the current waveform to get the RPM of the pump (Figure.

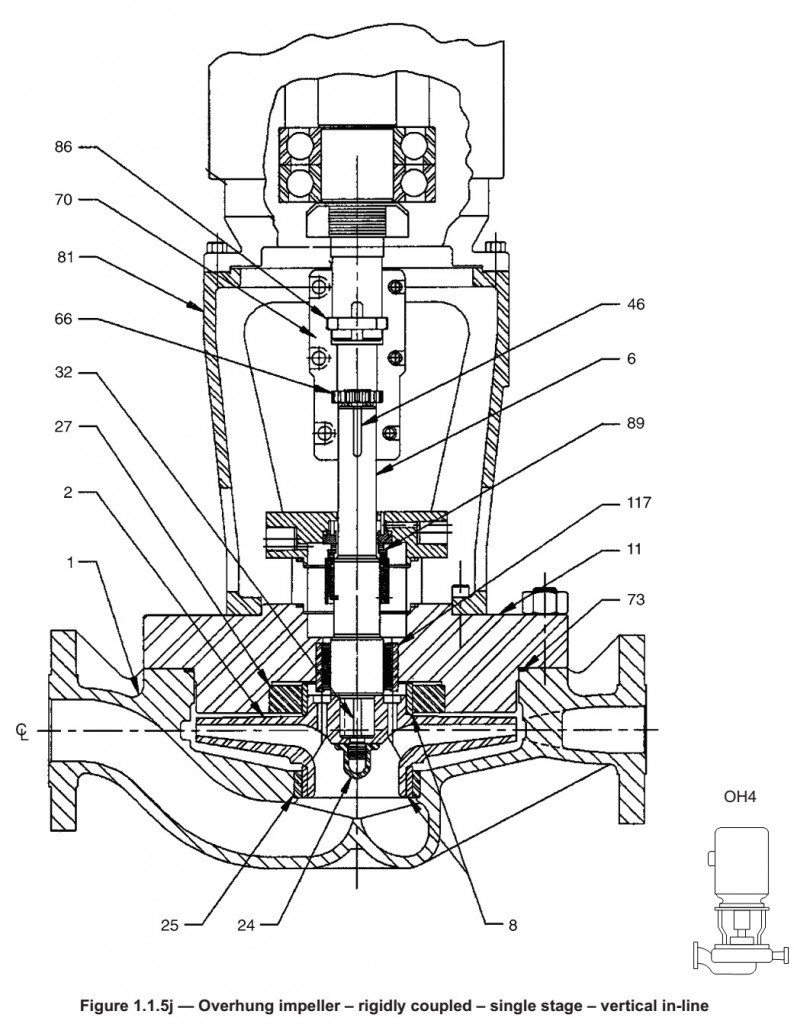

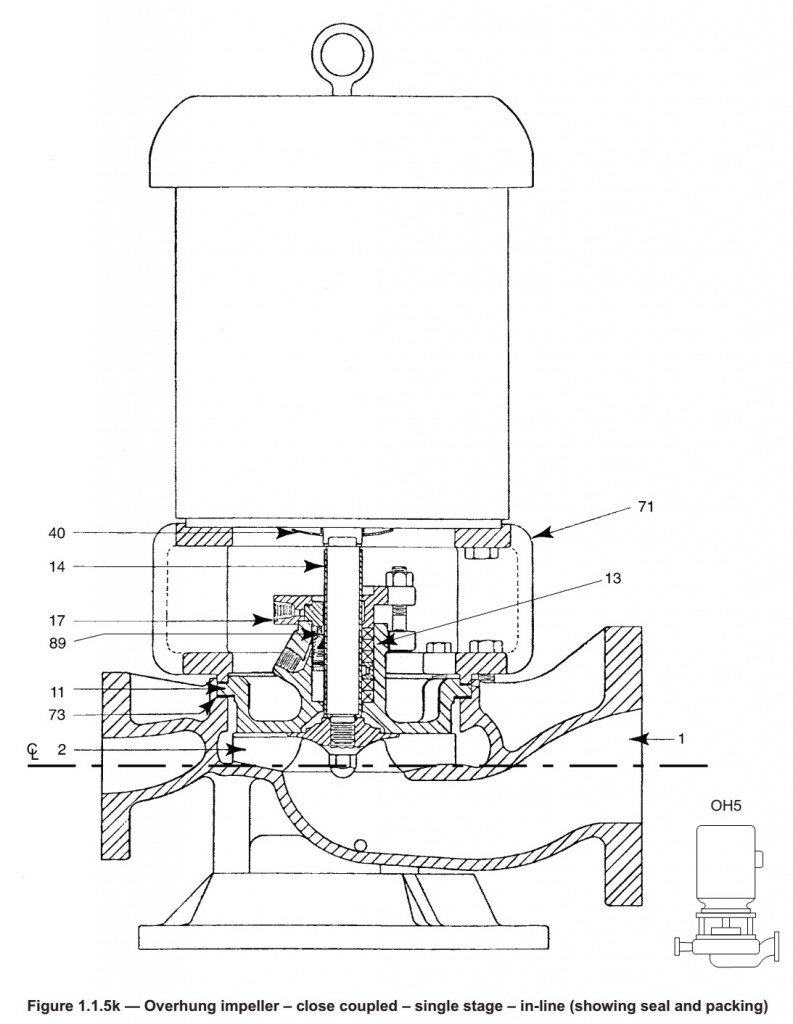

Vertical Inline Pumps Intro to Pumps

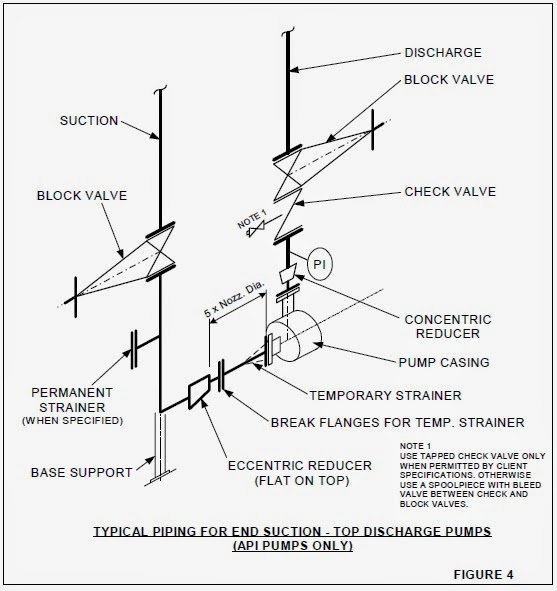

3. Steps to do Pump Piping. Step 1 : Collect the P&ID and the pump data sheet. Step 2 : Study the pump data sheet and collect the similar (capacity / head) pump dimensions / nozzle position. Step 3 : Analyse the location and the space provided in the unit plot plan w.r.t. suction and discharge line routing.

Vertical Inline Pumps Intro to Pumps

Here they are. Study the figures below and review the list of general guidelines that follows. The recommended suction inlet size D should be (0.0744Q)0.5, where Q is the flow in gallons per minute (gpm). The minimum width W of the intake structure, per suction inlet, in the direction of flow, should be. 2D.

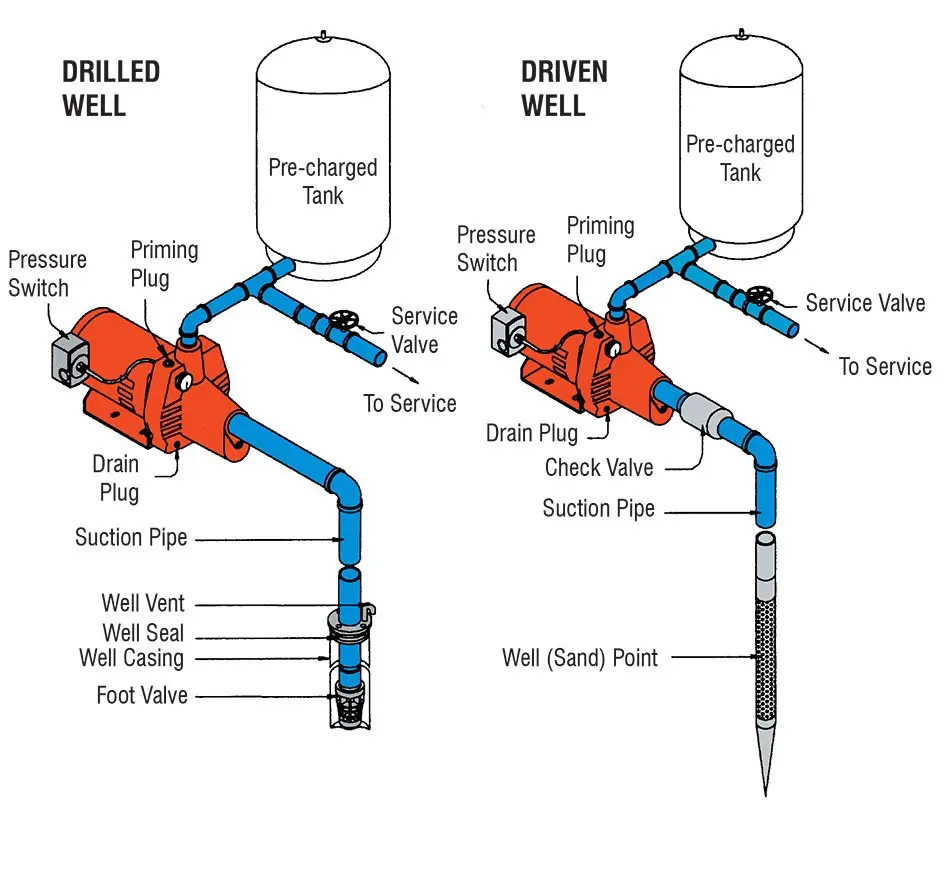

How to Install and Wire a Well Pump Well Pump Installation Guide

Identify the types of diagrams. Recognize Navy applications and component functions of hydraulic power drive systems. Recognize the construction features of hydraulic power drive systems. Recognize the operating characteristics of hydraulic power drive systems. Diagrams

Centrifugal Pump Diagram

As Gary Klein, an energy consultant and hot-water specialist, points out, "Compared to the time it takes hot water to arrive in 3⁄8-in.-dia. pipe at a given flow rate, it takes roughly 1-1⁄2 times as long in 1⁄2-in.-dia. pipe, three times as long in 3⁄4-in.-dia. pipe, and six times as long in 1-in.-dia. pipe."

Characteristics of Centrifugal Pumps Vertiflo Pump Company

Pump Curve. For example 30 gmp (1.89 L/s) for a 4.5 inch (114.3mm) impeller gives us about 13 feet (3.96m) of head but if we used a 5.5 inch (139.7mm) impeller then we would get around 22.5 feet (6.89m) of head. Pump Chart Examples. In some instances our required flow rate and head pressure might fall between the two impeller diameter lines.

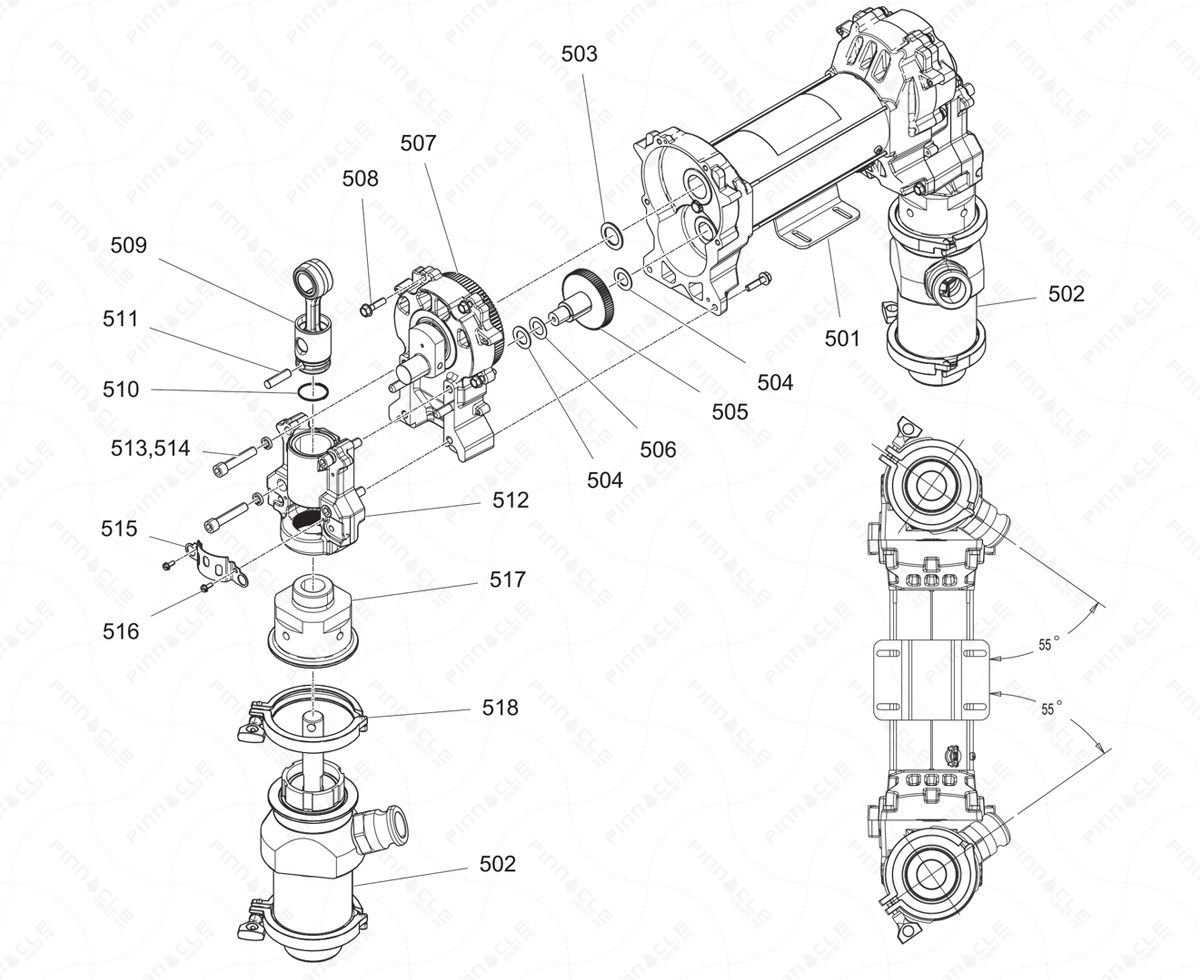

ToughTek F800e Pump Line Exploded Diagram Shop Online

PERMCO DUMP-PUMP TWO AND THREE LINE OPERATION. In applying the Permco Dump Pump, an understanding of the 2-line and 3-line circuits is essential for proper operation and maximum unit life. In the two line operation, one line is connected from the oil tank to the inlet of the pump and one line is connected from the cylinder port of the valve to.

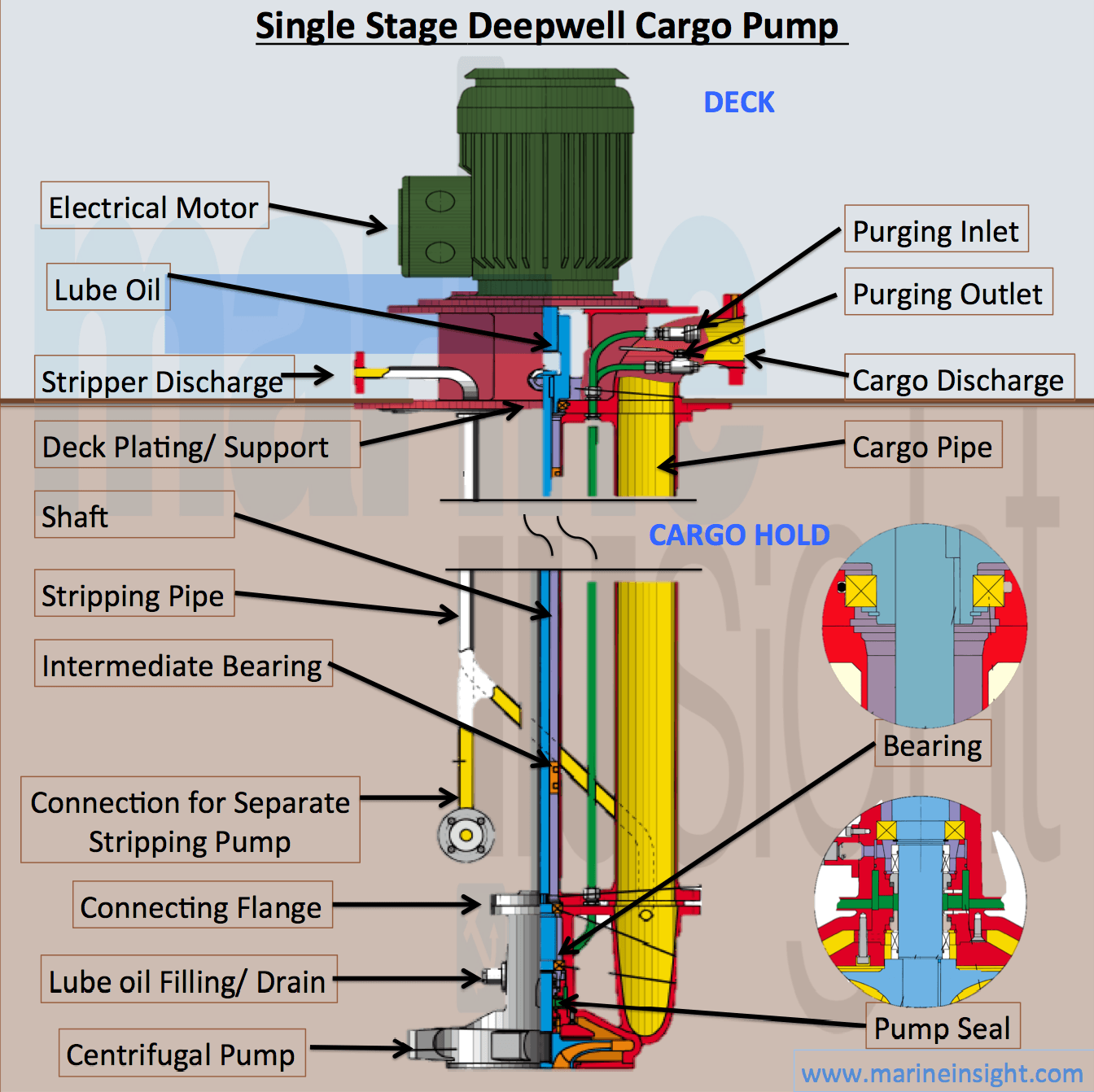

Infographics Single Stage Deepwell Cargo Pump

The pump-line-nozzle injection system is so-called for producing high fuel pressure in a pumping element, transferring the fuel pressure pulse through a high pressure injection line, and then spraying this fuel into the cylinder via the nozzle of an injector [113].

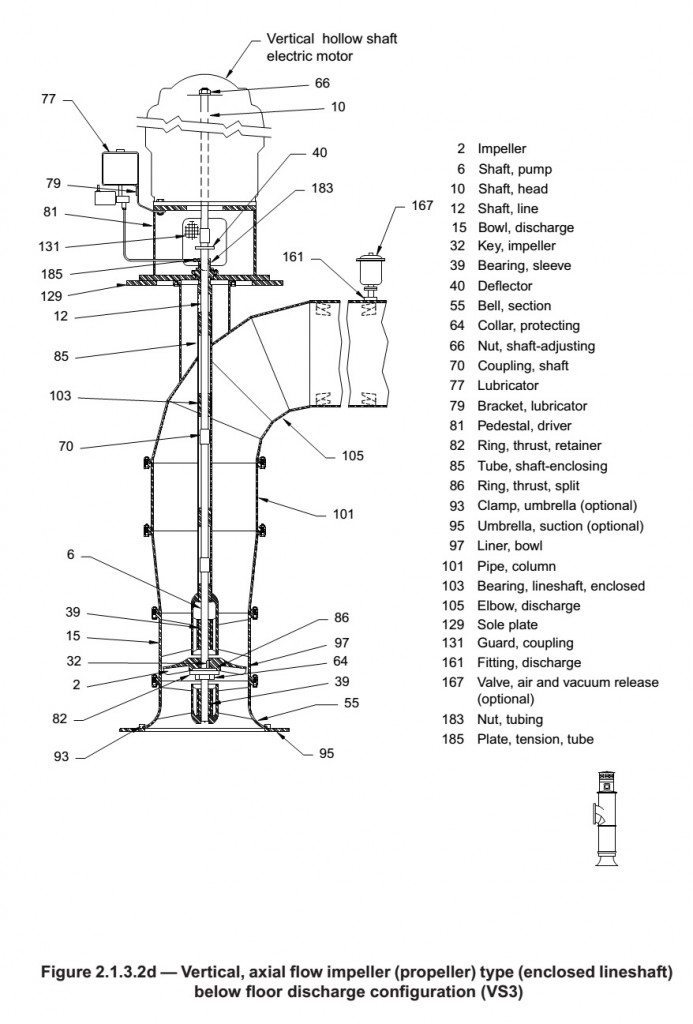

Vertical Turbine Pumps Intro to Pumps

diameter between the pump inlet and any obstruction in the suction line. Obstructions include valves, elbows, "tees," etc. Keeping the pump suction piping short ensures that the inlet pressure drop is as low as possible. The straight-run pipe gives users a uniform velocity across the pipe diameter at the pump inlet. Both suction. 2

Water Booster Pump Installation Diagram

The Process Operator will "swing the spectacle blinds" on the Pump Suction Line and Pump Discharge Line "to the closed position." The spectacle blinds on the diagram are those Figure 8 shaped things that look like spectacles (eyeglasses). Take the time to locate the "spec blind" on the diagram. It is between the Suction Gate Valve and the.

Pump Piping Design Considerations Make Piping Easy (2022)

Two Pump Single Heater Pool & Spa Plumbing Diagram 3 Jandy 3-Way Valves 4 Jandy Check Valves Common pool plumbing layout for two separate systems (pool and spa) sharing the same heater. Pool and Spa Combination with Ozone and Chemical Feeder 4 Jandy 3-Way Valves 1 Jandy 2-Way Valve 2 Jandy Check Valves 2 Jandy Valve Actuators